Residual Current Monitoring (RCM)

Protect production equipment and operators of green energy systems with RCM

Any leakage current can pose fatal and dangerous risks to your employees and production site. This includes production equipment within factories, such as CNC machines, semiconductor equipment, and new energy systems like charging piles, charging stations, and energy storage stations.

By using Danisense Residual Current Monitoring (RCM), you can protect production equipment and operators while avoiding costly equipment failures — even meeting legally mandated inspections (*).

Additionally, you can now access the Smart RCM equipped with PC software for data analysis, offering enhanced monitoring capabilities.

As power electronics devices become increasingly used in industrial and commercial installations, DC and high-frequency residual currents are generated, which may exceed the capabilities of traditional Type A residual current devices, rendering them ineffective.

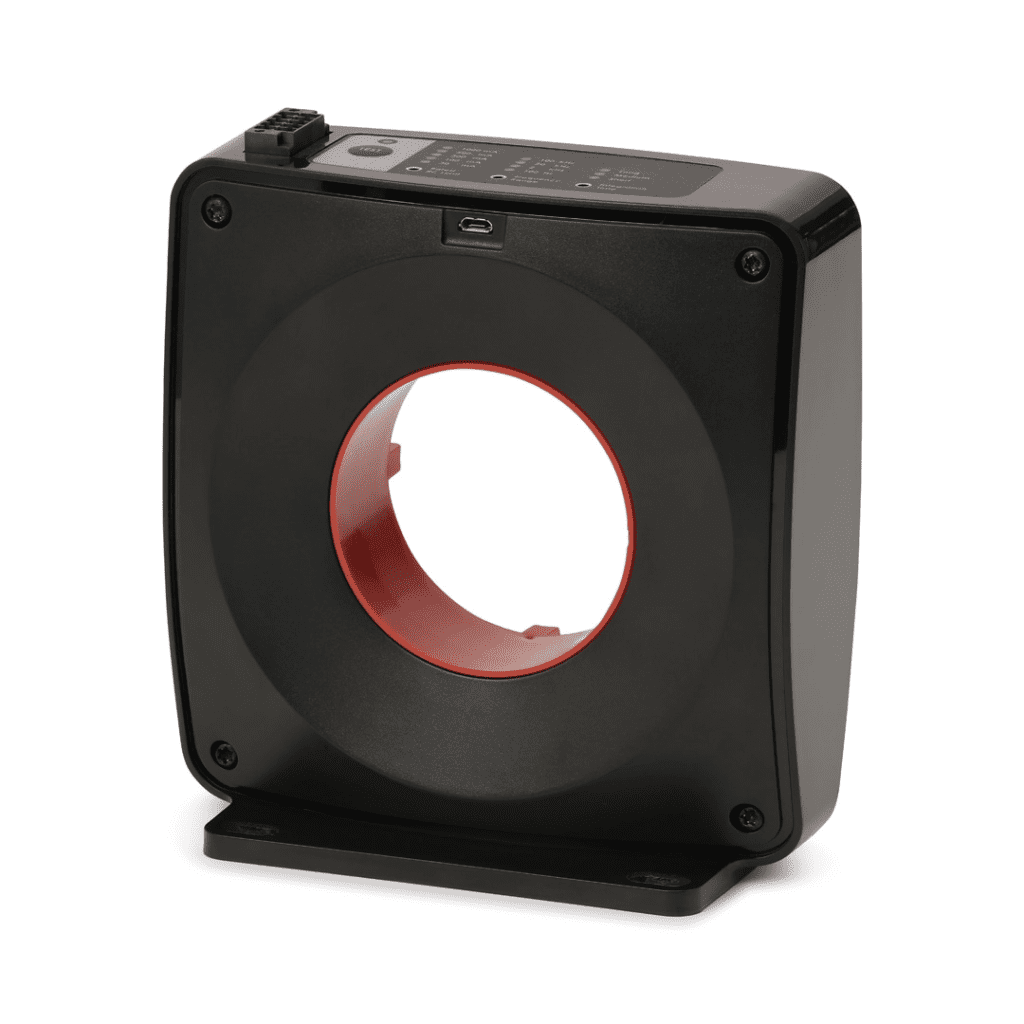

Leveraging its expertise in zero-flux technology, Danisense has developed a highly flexible range of Type B/B+ RCMs capable of measuring DC and AC residual currents up to 100kHz, with analog 4-20mA and relay outputs.

- Large aperture (70 mm)

- Adjustable rated RC thresholds (30, 100, 300, 500, and 1,000 mA)

- Configurable frequency ranges (100, 2,000, 20,000, and 100,000 Hz)

- Adjustable integration times (short, medium, long)

- Rated residual operating current fully compliant with the new IEC62020-1 standard

- Local or remote operation supported by PC software

Smart Residual Current Monitoring – RCM with PC software for data analysis

The latest version of Danisense RCM is controlled via PC (through USB) for data analysis, providing optimal monitoring features, including:

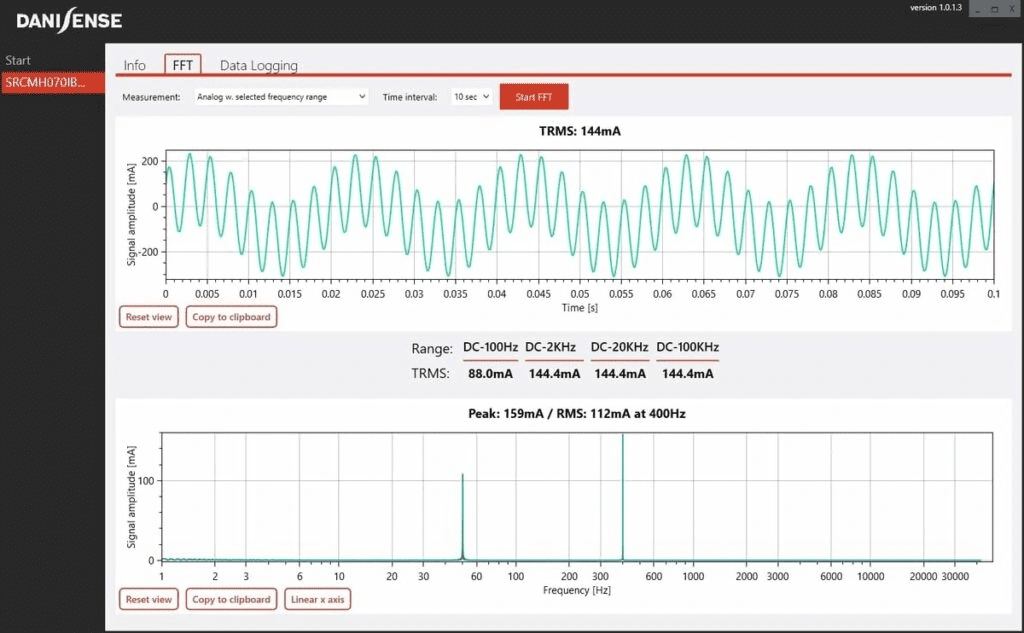

- FFT (Fast Fourier Transform): Spectrum analysis measurements

- Independent low-pass filter for TRMS calculation, allowing highly accurate TRMS computation via FFT

- Remote configuration of rated RC thresholds, frequency ranges, and integration times

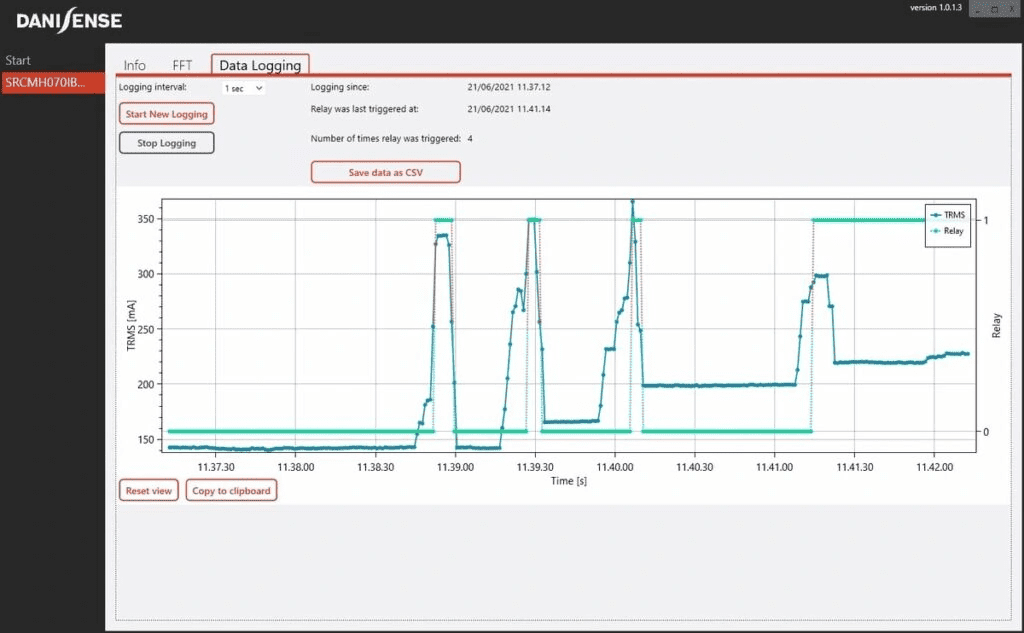

- TRMS time logs and data recording

- Relay triggers, e.g., information on the last residual current event

- (*) In Germany, production facilities must undergo testing and validation at least once every four years unless the company has installed Residual Current Monitoring (RCM).

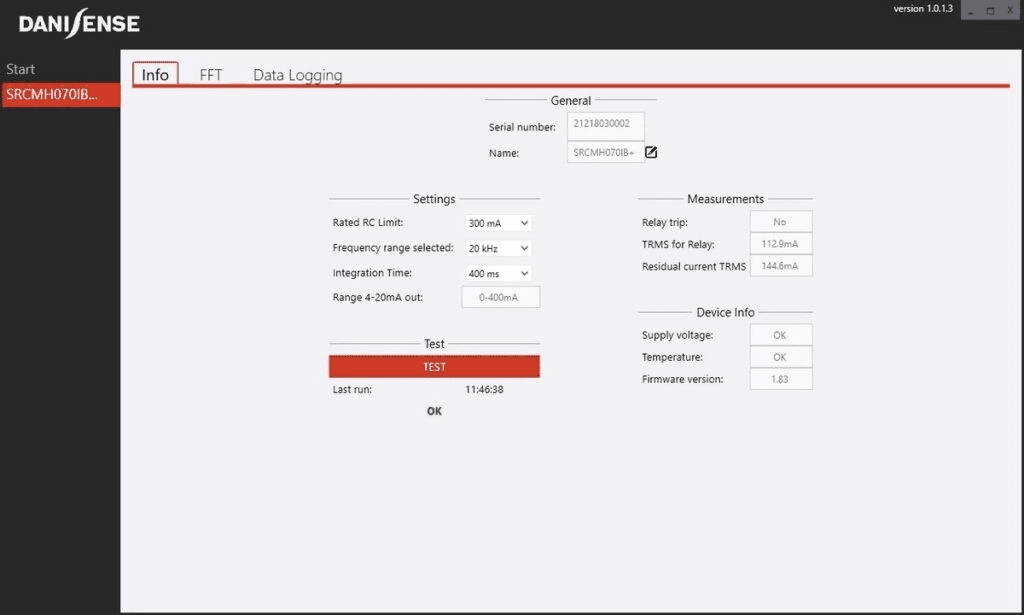

The "Info" screen provides an excellent overview, always displaying remote settings for rated RC thresholds, frequency ranges, and integration times.

Another feature is "Device Information," which shows power supply voltage, temperature, and firmware version. Additionally, relay testing is a useful function.

The FFT screen displays the measured spectrum and calculates TRMS corresponding to the frequency range.

Data logging records the TRMS data and relay status over time. Among these features, others include "Copy to Clipboard."

How does Residual Current Monitoring work?

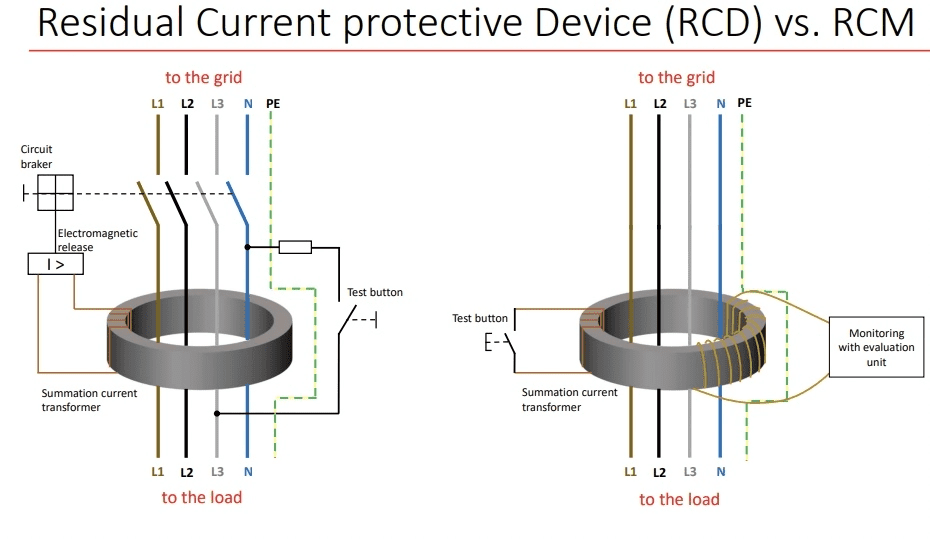

For decades, Residual Current Devices (RCDs) have been standard components in power distribution. Your home likely has an RCD rated at 30mA residual current. International standards mandate tripping between 50% and 100% of the rated residual current. For a 30mA RCD to trip, residual current must exceed 15mA. The 30mA threshold is designed to ensure electrical safety for humans, which is required for any freely accessible outlet. Currents above 50mA can be life-threatening.

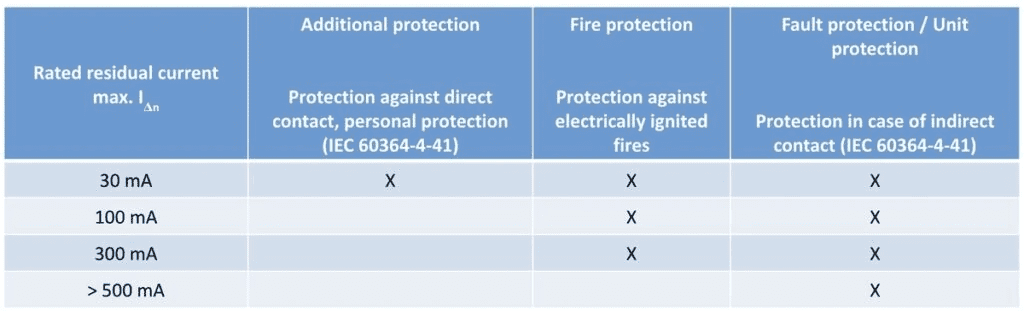

In manufacturing environments, large equipment is commonly used for production. Even if these machines are not directly connected to outlets, RCDs are often used to address various safety concerns, as illustrated by the three types of protection in the adjacent table.

System faults can lead to leakage currents and fires. Detecting minor defects early can prevent significant system damage. However, a major drawback of using RCDs for system protection is the unpredictable and sudden shutdown of systems. In critical industries, uncontrolled and unexpected shutdowns can result in substantial economic losses.

These issues can be addressed with Residual Current Monitors (RCMs). RCMs can detect and report increases in residual current at an early stage, reducing the likelihood of production downtime and enabling effective scheduling of equipment maintenance. RCMs are undoubtedly one of the essential tools for predictive maintenance.

The diagram clearly illustrates that, unlike RCDs, RCMs cannot independently interrupt power supply lines. Differential current is measured and output through appropriate interfaces. However, RCMs feature one or more relay outputs, which can control circuit breakers to achieve power disconnection.

What standards must Residual Current Monitors comply with?

IEC 60364-6 / IEC 62020

Residual Current Monitoring devices can provide significant added value for any company with equipment. As outlined in IEC 60364-6:2016, electrical installations or production facilities must undergo regular verification. This periodic verification is described as follows:

6.5.1.2 Periodic verification shall be carried out without dismantling or with minimal dismantling, supplemented by appropriate tests and measurements as outlined in Clause 6.4, to ensure the following:

- Safety for personnel and livestock from electric shock and burns

- Prevention of fire and heat-related damage to property caused by defects in electrical installations

- Verification of the correct ratings and settings of protective devices as required by IEC 60364-4-41

- Verification of the correct ratings and settings of monitoring devices

- Confirmation that the installation has no damage or deterioration that could compromise safety

- Identification of installation defects that may lead to hazards or are non-compliant with relevant parts of the IEC 60364 series

- Assurance of the correct ratings and settings of protective devices

- Assurance of the correct ratings and settings of monitoring devices

If power circuits are permanently monitored by Residual Current Monitors (RCMs) conforming to IEC 62020 or Insulation Monitoring Devices (IMDs) in accordance with IEC 61557-8, and if the IMD or RCM is correctly selected, insulation resistance measurements are not required.

The functionality of the RCM or IMD should be verified.

As we can see, it is explicitly stated that insulation resistance measurements in periodic verification can be replaced by residual current monitoring equipment conforming to IEC 62020. These devices continually monitor residual current and require ongoing maintenance by qualified electricians.

Another application area for RCMs is fire protection in production facilities. Approximately 30% of recorded fires can be traced back to faults or defects in electrical systems. Due to the high residual current associated with large equipment systems, protection using an RCD rated at 300 mA often results in nuisance tripping. This is where IEC 60364-4-42:2010+AMD1:2014 becomes relevant, stating that residual current monitors can be used alongside circuit breakers to prevent electrically ignited fires caused by insulation faults.

Therefore, it is strongly recommended to use residual current monitors conforming to IEC 62020 to fully leverage the benefits these devices provide.

Downloads

Specifications

| Model | Description |

|---|---|

| RCM | Residual Current Monitoring (RCM) |